Getzshape Revolutionizes Precision CNC Machining with Smart Factory Launch

Summary

Full Article

Getzshape has officially launched, marking a significant milestone in the precision CNC machining industry with its state-of-the-art smart factory. This development is set to address critical challenges such as slow quoting cycles, lack of project transparency, and the complexity of sourcing intricate components on demand. Founded in 2025 by a team of experts, Getzshape aims to redefine the manufacturing experience, making it smarter, faster, and more transparent for industries including aerospace, medical technology, robotics, and advanced electronics.

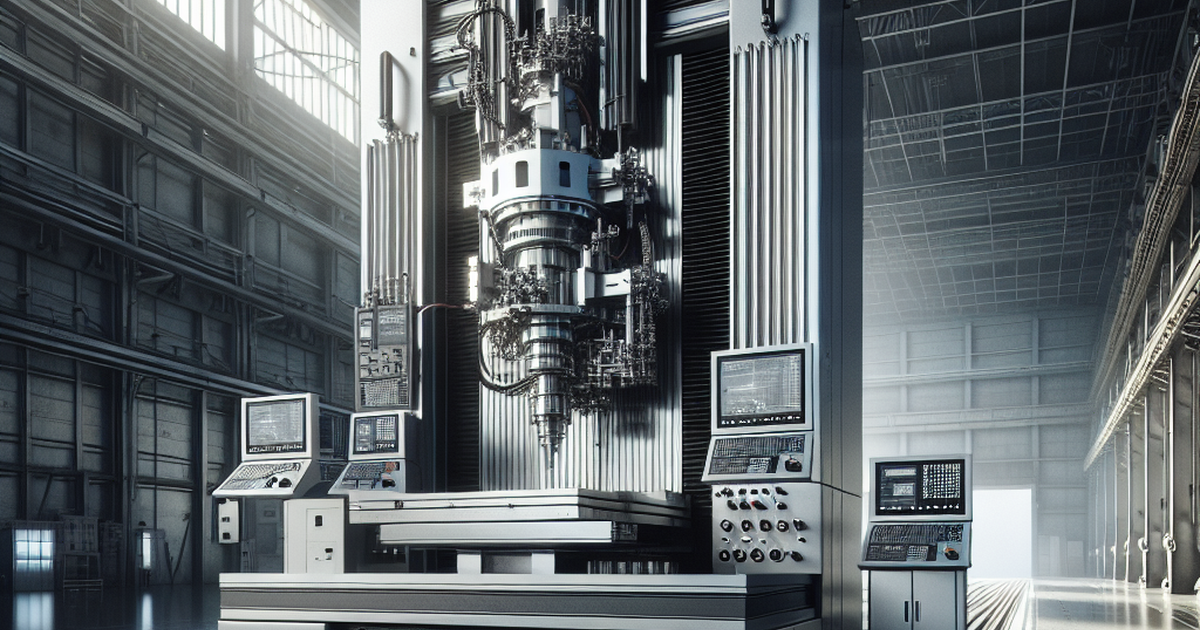

The company's founder, Lei Yang, highlights the vision of creating a manufacturing partner for the 21st century. Getzshape's approach is supported by cutting-edge equipment like advanced 5-axis machining centers and high-speed CNC turning lathes, ensuring direct communication and comprehensive quality assurance for clients. This integration of technology and transparency is expected to set new standards in the industry.

At launch, Getzshape offers services such as multi-axis CNC milling and turning, rapid prototyping, and engineering consultation, all designed to meet the needs of modern engineering. The company's ISO 9001:2015 certification underscores its commitment to excellence and the highest industry standards. For more information on their services, visit https://www.getzshape.com.

The implications of Getzshape's market entry are profound for industries reliant on precision machining. By prioritizing customer partnership and transparency, the company is not just producing parts but is also paving the way for the future of manufacturing. This development could lead to faster product development cycles, higher quality components, and more efficient sourcing processes, ultimately benefiting the global supply chain.

This story is based on an article that was registered on the blockchain. The original source content used for this article is located at 24-7 Press Release

Article Control ID: 127650